The vehicle in this article is a Citroen DS3 1.6 Diesel and after a brief chat with the customer regarding driving style,service history and journey types we then discussed the symptoms of excessive black smoke when the revs were increased .

The vehicle in this article is a Citroen DS3 1.6 Diesel and after a brief chat with the customer regarding driving style,service history and journey types we then discussed the symptoms of excessive black smoke when the revs were increased .

Driving the vehicle into the workshop confirmed the symptoms the customer described , thick black clouds of smoke were clearly visible.

I carried out some visual checks in the engine bay , oil level was perfect and also coolant level was as expected. Next step was to interrogate the ECU for fault codes , there were none .

If you have read my previous posts on this blog you will know I am a great believer in process , which often involves stepping away from the vehicle for 10 minutes and building a test plan so I am not aimlessly testing components in the hope of stumbling across the faulty part/s . So this is what I did next , writing down the possibilities of what could be causing the smoke and what tests/data I need to evaluate in order to either prove what is working or what is not working as it should.

On a vehicle which has only done 30,000 miles and had dealer servicing and mixed driving conditions , I was going to be looking at Fueling , Air intake and EGR as all other possibilities as the other options I would not expect to see on a car in this condition.

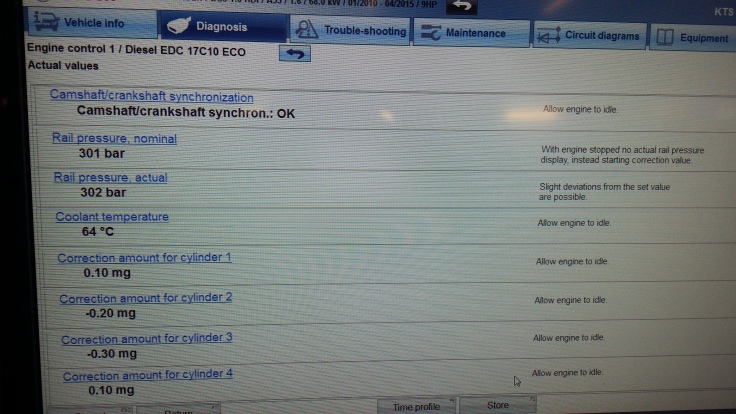

First thing to check was fuel rail actual and nominal values in the data from the scan tool against engine speed , cranking and idle they were identical with good cranking speed and under load also as expected. after raising the rpm and left to idle I switched the engine of to observe the speed at which the rail pressure dropped as this is a great indicator of injector leakage, the pressure slowly reduced over about 8 – 10 seconds which i was happy with . Also a quick check of the injector quantity comparisons confirmed that I was not looking at an injector fault at the moment.

Next up was to check the intake for leaks with a smoke test and this checked out absolutely fine so I now know we have no false ambient air .

Another parameter I checked was Cam Crank synchronisation which could point to a timing/pump problem , this also checked out ok.

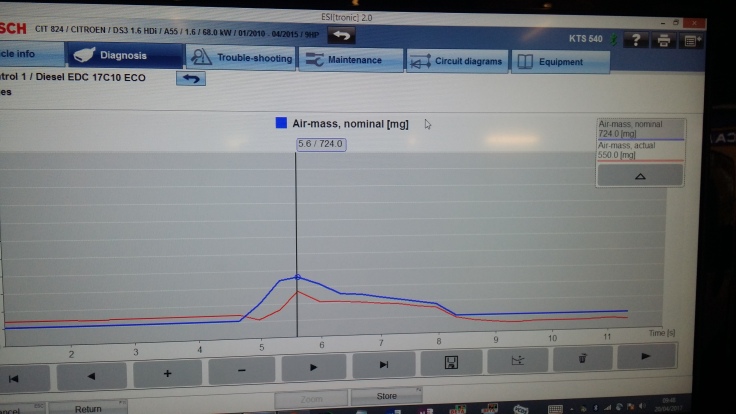

So far I was happy that I had ruled out a few of my initial possibilities quite quickly which left EGR and mass air flow data. MAF was my next test and this was the first piece of data that indicated an clear issue . I monitored the actual value against the nominal value and there was a clear deviation between the two (seen below)

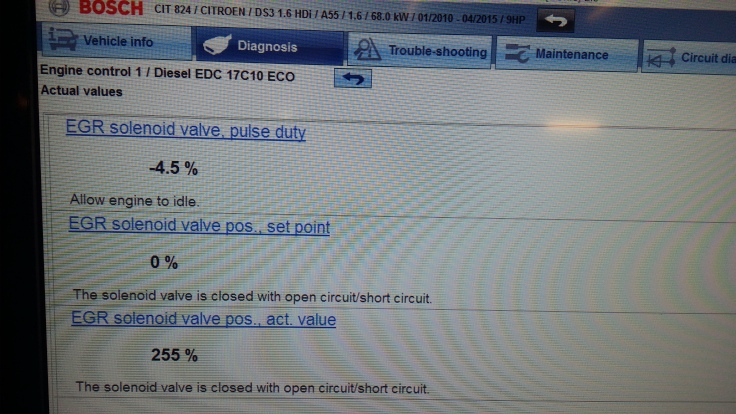

This proved that the volumetric efficiency of the engine was being comprimised , so that led me into my next test , if it was not false air(which I had already proved) then it had to be EGR ! I took at look at the data (seen below) which proved further investigation was needed for the EGR system as the actual value for EGR position was 255% and at idle should be 0-2% !!!

After a chat with the customer explaining my findings the EGR was removed ,inspected and renewed and the vehicle was now back to its former glory with no smoke .

I hope this shows that without any fault codes all that is needed is a logical thought process which usually involves proving was is working to find what is not working whilst gathering evidence to warrant removal of a component.

You can view more of Glenn’s work on his Definitive Diagnosis Blog or visit and subscribe to his Definitive Diagnosis Youtube channel. You can also follow him on Twitter for his latest thoughts and updates – @GlennNorris

You must be logged in to post a comment.