Over 10 years after the Verification of Lubricants Specifications (VLS) was formed, the organisation has highlighted the significant work that is still needed to protect the lubricants industry.

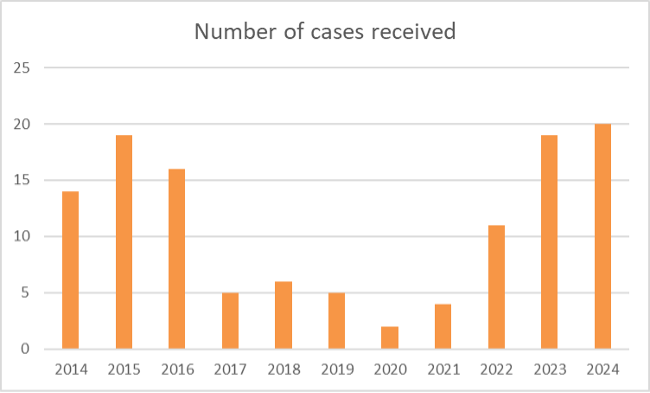

To mark its decade of existance, VLS published a white paper highlighting the types of cases investigated during this period. At that time, it had looked into 91 complaints. Yet 12 months later, this figure has risen to 121. In the past two years, 39 cases have been opened, more than in the preceding six-year period.

‘’When VLS was first formed in 2013, there was clearly a lack of understanding in some areas of the marketplace,” commented Alan Outhwaite, Chairman, VLS Technical Review Panel. “Eleven years later, we are confident that the message around compliance is being heard. However, the significant rise in cases over the past 12-18 months and the complexity of those cases demonstrates that there is still work to do to ensure an open and fair marketplace that end users can have confidence in.”

Car oil dominates VLS cases

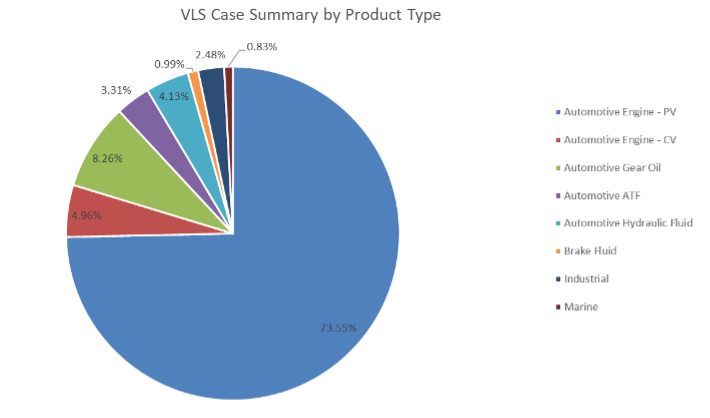

The vast majority of cases investigated by VLS relate to passenger vehicle engine oils. This indicates not only the size of the Passenger Vehicle (PV) market in comparison to other sectors but also the level of complexity required to serve this consumer-orientated market.

These oils make up 73.5% of all cases that VLS looks into, with the rest of the investigations split between gear oils, commercial vehicle engine oils, hydraulic fluids, and other lubricants.

The product type of cases received remains broadly in line with the split from 2023. The notable change is the rise in the percentage of commercial vehicle engine oil cases and automotive hydraulic fluid cases.

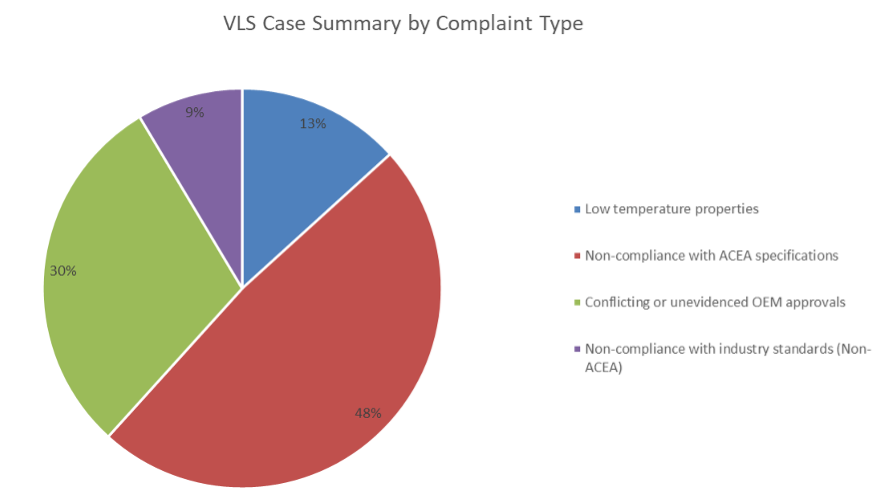

However, conflicting or unevidenced OEM approvals, non-compliance with industry standards and low temperature properties have all increased their share of overall complaints. In 2024 to date, half of the cases opened have related to conflicting or unevidenced OEM approvals.

Whether it be compliance with the ACEA’s European Engine Oil Sequences, other market standards or conflicting or unevidenced OEM approvals, it is vital that any end user can be confident that a product can deliver what it claims and is suitable for use in the given application. Lubricant marketers should regularly audit products, technical data sheets, and claims to ensure that products are in continued compliance.

Vigilance required

Over time, specifications can change, and therefore, marketers need to remain vigilant, or risk providing a substandard product that no longer meets the requirements of the vehicles it is specified to work with.

For example, VW 504.00/507.00 has kept the same specification reference, but some tests behind it have been updated, and the severity has changed. Lubricant manufacturers cannot assume that because a product meets a specification at a given time, it will continue to do so during the lifetime of the specification. Requirements change, and only regular auditing and testing through comprehensive Quality Management Processes can ensure that products remain compliant.

This issue can be explained by looking at the case VLS 010187, looking at John Neale Coolant CS-AQ Aluminium Synthetic Cutting Fluid. This case demonstrated VLS’s ability to extend its impact beyond the automotive sector, being recognised by the Health & Safety Executive. In 2023, VLS received a complaint that the product’s ‘No mist hazard’ claim on the Technical Data Sheet was misleading.

Whilst the formulation may contain no mineral oil, other components present, bacteria/fungi or tramp oil could form a mist when the product is in use. The MSDS indicated the presence of PYRIDINE-2-THIOL 1-OXIDE, SODIUM SALT, which is classified as ‘toxic if inhaled’. According to HSE MW5, which states “water mix MWF”… “Inhalation of MWF mist can cause lung disease”. The product also claimed to help users meet their oil mist limits, when there are no limits published.

Reference was made to zero bacterial growth after 12 months in operation, and VLS asked for this to be evidenced and under what conditions. The product claimed to be ‘sensitiser free’, but the MSDS indicates the presence of PYRIDINE-2-THIOL 1-OXIDE, SODIUM SALT, which is a known sensitiser.

In response to the complaint, the Lubricant Marketer replaced sodium pyrithione in the formulation with a suitable alternative. They also revised the product’s Technical Data Sheet claims and brought them into compliance.

Reformulation options

In many cases, lubricants have been reformulated to bring them into compliance. Case VLS 010201 was closed after Aztec Oils took swift action to withdraw the claim against Renault’s RLD-4 specification, which was not supported by the manufacturer, against their Emprotec UHPD 10W40 Heavy Duty Engine Oil (HDDO).

They retained the claim against RLD-3 and amended the product’s description and Technical Data Sheet accordingly. VLS was content that the product had been brought back into compliance, and the investigation was closed. The case proved to be in continued compliance at the standard six-month review.

However, several cases have also been referred to Trading Standards due to non-compliance. VLS issued a safety warning and escalated case VLS 010200, a complaint regarding Mannol Brake Fluid DOT 4 3002, to Trading Standards earlier this year. Independent testing proved the product failed to meet specification limits stated in the US Federal Motor Vehicle Safety Standards (FMVSS) 116 DOT 4.

Lubriage Ltd, trading as Mannol UK, the product’s distributor, advised that they had stopped selling the product in the UK marketplace and asked distributors to quarantine the affected batch number until further notice and not resell it.

However, VLS did not see any evidence of the product being quarantined or withdrawn from the relevant distributors or any attempt to contact end users who might have purchased the product through their distributors, to recall it. VLS escalated the case to its Primary Authority partner, Buckinghamshire and Surrey Trading Standards, as a consumer product safety issue to ensure sufficient action was taken to protect driver safety.

VLS 010195, a complaint regarding Silverhook 5W30 Supreme Plus, was escalated to Trading Standards SAIL-Europe under the EELQMS Lubricant Marketer Letter of Conformance after the company failed to bring the product into compliance.

VLS reviewed and upheld a complaint regarding ambiguous, inaccurate and mutually exclusive claims. Evidence of support for claims was not provided, and the Technical Review Panel felt sufficient action had not been taken to remove mutually exclusive claims or clarify claims being made.

The Primary Authority relationship with Buckinghamshire and Surrey Trading Standards, which VLS entered into in 2020, has proved effective in concluding certain cases where escalation by exception has been required to prompt action.

Testing times

Testing has continued to play a critical role in investigations. In a recent hydraulic oil case, the lubricant manufacturer said they recalled stock and reformulated the product. VLS accepted the evidence they provided. At the six-month review stage, VLS purchased a product sample, which failed again.

Varol, the lubricant manufacturer, said the sample had been purchased from a distributor, which was old stock still in the marketplace. A third sample was procured, which produced a perfect result. Testing demonstrated the importance of tracing non-compliant products throughout the supply chain to protect end users.

The lubricants industry has been through immense change since VLS was formed in 2013, and the pace of change shows no sign of abating

Electric vehicles now have a much larger share of the vehicle parc, even if sales have stalled recently. Hybrid vehicles place immense stress on lubricants, with longer warm-up times and engines starting at high speeds and high revs once battery power has been exhausted. Lower viscosity fluids have continued to become more commonplace, but the vehicle parc is ageing. The latest 0W-8 oil could cause damage in an older vehicle, which requires a 5W-40, starving the engine of the protective lubricant film it needs and leading to increased wear.

Importance is clear

“Additives play a vital part in lubricant performance, delivering a variety of characteristics to combat wear and corrosion, disperse soot and prevent the build-up of deposits whilst ensuring compatibility with emission control devices,” added Outhwaite. “Along with the proliferation of lubricant products in general, VLS is concerned about the integrity of products from new companies entering the additives market. Their additives may be cheaper, but they may also not be fully tested or approved as published industry and OEM specifications require. This market development is one VLS is monitoring closely, as additives are a critical aspect of lubricant formulations.

“VLS continues to be incredibly grateful to the members of the Technical Review Panel and their organisations for their support. Without their expertise and our robust, anonymous process, we would not have the skills and resources required to adequately investigate products and work with Lubricant Marketers to assist them in taking the required action to bring products into compliance.

“As our industry rises to the continuing challenges of even greater change and complexity, their technical expertise will be even more valuable than ever to support lubricant blenders, manufacturers, and distributors and protect end users,” he concluded.

You can find out more about VLS and keep up to date with the latest case investigations at the VLS website: https://ukla-vls.org.uk/

If you have any concerns about a lubricant’s ability to deliver what it claims, you can report your concerns to VLS by calling 01442 01442 875922 or emailing admin@ukla-vls.org.uk.

You must be logged in to post a comment.