Headlight glare has been a trending toping in 2025, with many media outlets picking up on stories of drivers being dazzled during nighttime driving.

Many are blaming LED lights for the rise in incidents of headlight glare. However, non-replaceable LED light units that are fitted to vehicles at the point of manufacture comply with the legal regulations around light output, otherwise they would not be allowed to be fitted.

Yet using its state-of-the-art lighting laboratory located at its headquarters in Leeds, UK, lighting and automotive electrics supplier Ring has found that there are bulbs that are not road legal that may be causing glare.

Potential for headlight glare

LED retrofit bulbs that are for off use only are being used on the road in headlamps that were designed for halogen bulbs. It is these LEDs that are more likely to be a contributor to headlight glare. The headlamp unit was not designed to work with the light output from LED bulbs.

While LED bulbs sales have gone up, the majority of bulb sales for headlamps still remains halogen bulbs.

The worrying trend from Ring’s findings is that the market is seeing an influx of poor-quality halogen bulbs that do not meet necessary standards and as a result could be causing headlight glare.

Using its lighting laboratory, and testing various bulbs that are available on the UK market, the company has found some worrying trends. According to their study, there are bulbs being sold in the UK that are not compliant with current legislation and are therefore, not road legal.

Vehicle bulbs used on the exterior of a vehicle must comply to ECE Regulation 37 that details exact specifications such as: light output, minimum and maximum levels, so drivers can see safely, and other road users are not dazzled by headlight glare.

Filament geometry makes sure the light is directed on the road exactly where it is needed. Voltage, so it is suitable to work in particular vehicles and wattage, so that brightness levels are safe and does not damage wiring.

These regulations are in place to ensure that road users are safe. It is illegal to fit light assemblies that carry their own performance approval numbers with bulbs that are not E approved (1989 Road Vehicle Lighting Regulations).

Laboratory testing

When testing bulbs in the lab, the laboratory team use multiple bulbs of the same type from the same brand. This ensured their performance or any issues that occur, are constant, and not just a one off.

Included in the testing were bulbs supplied by one company which all exceeded the maximum wattage and lumens levels by a considerable margin. Another was more than 26% above maximum lumen output, and the wattage was 49% above maximum. At this level, the bulbs could cause overheating to a vehicle‘s wiring, as well as causing headlight glare for other road users.

In another instance, one of the bulbs was switched on and, after only a few minutes, the chrome end cap showed signs of deterioration. There were also many incidents of bulbs not complying with ECE Regulation 37, non-conformity which makes the bulb not road legal.

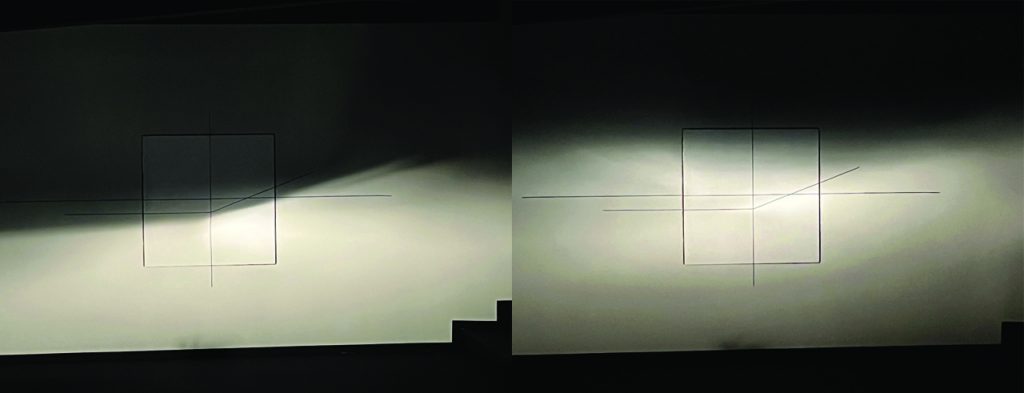

Ring also conducts photometry tests, and from one bulb supplier, four of the ten samples failed photometry on the 5W filament, which was too high. In other instances, bulbs did not meet the amber colour requirement, and many had a poor beam pattern, which will cause glare.

Responsibility present

“We regularly test ranges of halogen and auxiliary bulbs sold in the automotive industry,” commented Andy Gratton, Managing Director at Ring Automotive, a subsidiary of ams-OSRAM.

“We have a responsibility to the aftermarket to ensure that distributors and technicians are clear and confident that the bulbs they sell, and subsequently fit to consumers vehicles, are safe, compliant and produced to the highest quality standards. These are safety critical products and, as such, regulation compliance is not optional.

“We tested a number of recognised brands, and these results revealed that some bulbs sold are not road legal in relation to Regulation 37 of the ECE standard. There is an increasing awareness amongst road users of the impact of poor-quality vehicle lighting and our objective is to continue to raise awareness of the causes of issues, such as low visibility and, at the opposite end of the spectrum, headlight glare.

“Our findings identified through testing at our quality facilities in the UK and Germany represent a real challenge for the independent automotive aftermarket. Whilst bulbs are low-cost relative to other ‘hard parts’, they remain a safety critical component of a vehicle and should be considered as such.

“There really is no excuse, given the relative cost, for road users to be subjected to a non-compliant product. We remain committed to improving road user safety in the UK and will ensure that the issues identified follow the correct reporting procedure.”

The issue of headlight glare is only likely to continue. While non-standard and illegal bulbs are a contributors, there are also other potential factors at play, including improperly-aligned lights, and the rise of higher-fronted SUVs. Ultimately, the aftermarket can play its part by ensuring all cars serviced, and bulbs fitted, comply with regulations.

You must be logged in to post a comment.